Light Colour MDF physicial properites

No. |

Test Items |

Technical Specification |

Unite |

Test Result |

1 |

Moisture Content |

4~13 |

% |

5.8 |

2 |

Density |

450~880 |

Kg/m3 |

730 |

3 |

Density Tolerance |

±7.0 |

% |

±1.4 |

4 |

Expansion ration in thickness due to water absorption |

≤10 |

% |

8.8 |

5 |

Internal bonding |

≥0.45 |

Mpa |

0.49 |

6 |

Modulus of rupture |

≥20 |

Mpa |

26.8 |

7 |

Modulus of elasticity |

≥2200 |

Mpa |

3280 |

8 |

Screw holding |

Face≥1000 |

N |

1120 |

Side≥800 |

870 |

9 |

Surface bonding |

|

Mpa |

1.28 |

10 |

Formal Dehyde Emission |

E1: ≤9.0 |

mg/100g |

4.9 |

E2: ≤30.0 |

20 |

MDF colour and material :

100% poplar material with white colour

100% pine material with light yellow colour ,

70% poplar or 70% pine mix 30% hard wood with normal colour ,

MDF specification :

Size: 1220x2440mm,1830x3660mm,2070x2500mm,2100x2500mm, 1830x2745mm etc,

1220x2440mm is normal sizes , for other sizes will manufacture according to buyers’ order.

Thickness:2.0-30mm

MDF has many advantages as following ,compared with other man-made board,

1,Uniform plate density, excellent physics performance; It's close to natural wood but better than natural plank.

2,High strength and good dimensional stability, thickness is 2.5mm-30mm, it has been widely used.

3,Good mechanical processing performance, It may use natural wood processing equipment and methods for machining.

4,Flat surface,so It is easy for secondary processing.

MDF Widely applications:

Furniture, building, decoration ,vans appliances and acoustics industries.Due to the excellent properties of MDF, Currently has widely applied in high-grade .

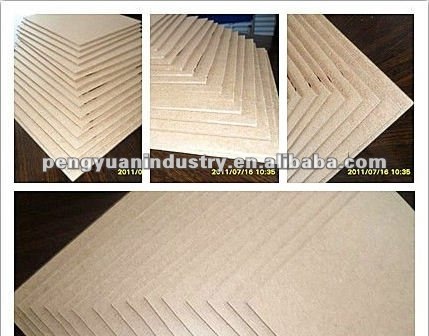

Photo show: